Uniform Circular Motion

Equipment

Procedure

- Warning! This is one of the few mechanics experiments that

can seriously injure you. Keep your hands and loose clothing well

away from the quickly rotating cage.

- We will determine the force required to stretch a spring of unknown

force constant a given distance in two ways:

Method 1:

- Record the number of grams stamped into the mass. The manufacturer does not quote an error estimate. What is probably the error in this quantity?

- Measure the radius of circular motion by measuring the distance from the center of rotation (marked by a small line on one side of the cage) to the center of the mass (marked by a line around the cylindrical mass) when the spring is extended just enough to trip the indicator. Record an error estimate. This measurement can only be mede while the cage is held vertically during method 2.

- Measure the spring extension by measuring distance from the center of rotation to the point where the spring is attached to the cylinder when the spring is extended just enough to trip the indicator. Record an error estimate. This measurement can only be mede while the cage is held vertically during method 2.

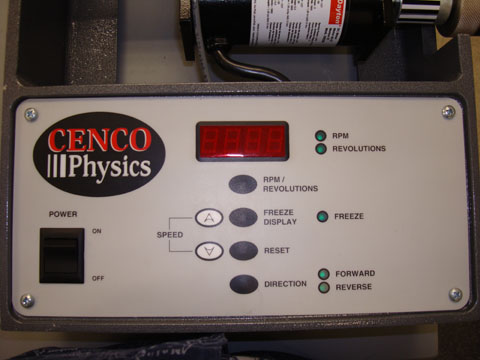

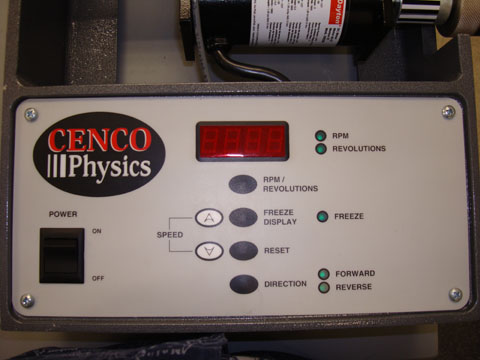

- Attach the cage to the digital rotator, increase the speed of rotation and note the speed when the trip lever points to the center of the bead on the rotation axis of the spinning cage; this is the desired speed.

The speed control circuit of the rotator works like a temperature thermostat. The thermostat is set at the desired temperature (the set point) and controls the AC unit. Cooled air is delivered until the room temperature is a few degreeas below the set point, at which time the thermostat turns off the AC unit. The temperature of the room gradually rises until it is a few degrees above the set point; the thermostat then turns the AC unit back on to deliver cooled air to the room. This cycle continues repeatedly and the room temperatue fluctuates sinusoidaly about the desired set point.

The Speed Control Circuit (SCC) of the rotator keeps the speed of the rotating cage fluctuating about the set speed (the set point). The typical variation in speed is from +/- 2 rpm to +/- 6 rpm with cycle times of 30 to 90 seconds depending the particular rotator being used.

The speed control circuit of the rotator works like a temperature thermostat. The thermostat is set at the desired temperature (the set point) and controls the AC unit. Cooled air is delivered until the room temperature is a few degreeas below the set point, at which time the thermostat turns off the AC unit. The temperature of the room gradually rises until it is a few degrees above the set point; the thermostat then turns the AC unit back on to deliver cooled air to the room. This cycle continues repeatedly and the room temperatue fluctuates sinusoidaly about the desired set point.

The Speed Control Circuit (SCC) of the rotator keeps the speed of the rotating cage fluctuating about the set speed (the set point). The typical variation in speed is from +/- 2 rpm to +/- 6 rpm with cycle times of 30 to 90 seconds depending the particular rotator being used.

- Set the SCC of the rotator to the desired speed noted above and measure the cycle time. Change the display mode of the rotator from RPM to Revolutions. Simultaneously reset the display and start the stop watch. Time the revolutions for at least 2 cycle times, then simultaneously freeze the display and stop the stop watch. Record the number of revolutions and time. The Revolution display is digital, use the lab rule of thumb to determine the error estimate in the number of revolutions. If the same person runs the stop watch and controls the rotator, then the full precision of the stop watch may be used. If one partner controls the rotator while another partner runs the stop watch, then the time measurements are limited by the reaction time of the partner using the watch. Repeat for a minimum of four trials.

- From these data, determine the force (in newtons) required to trip

the indicator. Include an error estimate. (Do not get a

numerical value for the speed, and do not solve for the error in

the speed. You want a formula for the force in terms of only the

quantities that you measure in lab and speed is not one of them.)

Method 2:

- Loosen the motor position knob and rotate the motor into its horizontal position, tighten the knob, the cage should now be vertical. Hang masses from the string attached to the cylinder until the indicator just trips. For the error in the

hanging mass, decide how much mass you can add or subtract from the

hanger without noticing a difference.

- Determine the force (in newtons), with an error estimate, required to trip the indicator. Remember that the mass of the hanger is 1000 grams. Should you include the mass of the spinning cylinder? Why or why not?

Error analysis

- Do the two forces determined have overlapping error estimates?

- Which determination of the critical force is more reliable? Why?

- Assume that the equilibrium position of the spring is at the center

of rotation. What is the spring constant of the spring in MKS units?

No error estimate is required here.

- In Method 2, should you include the mass of the spinning cylinder?

Why or why not?

- Identify at least two sources of statistical error.

- Identify at least two sources of systematic error.

Back to the Mechanics Manual

Back to the Mechanics Manual

The speed control circuit of the rotator works like a temperature thermostat. The thermostat is set at the desired temperature (the set point) and controls the AC unit. Cooled air is delivered until the room temperature is a few degreeas below the set point, at which time the thermostat turns off the AC unit. The temperature of the room gradually rises until it is a few degrees above the set point; the thermostat then turns the AC unit back on to deliver cooled air to the room. This cycle continues repeatedly and the room temperatue fluctuates sinusoidaly about the desired set point.

The Speed Control Circuit (SCC) of the rotator keeps the speed of the rotating cage fluctuating about the set speed (the set point). The typical variation in speed is from +/- 2 rpm to +/- 6 rpm with cycle times of 30 to 90 seconds depending the particular rotator being used.

The speed control circuit of the rotator works like a temperature thermostat. The thermostat is set at the desired temperature (the set point) and controls the AC unit. Cooled air is delivered until the room temperature is a few degreeas below the set point, at which time the thermostat turns off the AC unit. The temperature of the room gradually rises until it is a few degrees above the set point; the thermostat then turns the AC unit back on to deliver cooled air to the room. This cycle continues repeatedly and the room temperatue fluctuates sinusoidaly about the desired set point.

The Speed Control Circuit (SCC) of the rotator keeps the speed of the rotating cage fluctuating about the set speed (the set point). The typical variation in speed is from +/- 2 rpm to +/- 6 rpm with cycle times of 30 to 90 seconds depending the particular rotator being used.

Back to the Mechanics Manual

Back to the Mechanics Manual